Lamination is a pivotal stage in the production of materials for automotive interiors, where it involves the adhesion of textile components to foam substrates. This process is essential for optimizing both the sensory properties and technical attributes of the materials.

Capabilities

Lamination

Trim Cut and Sew

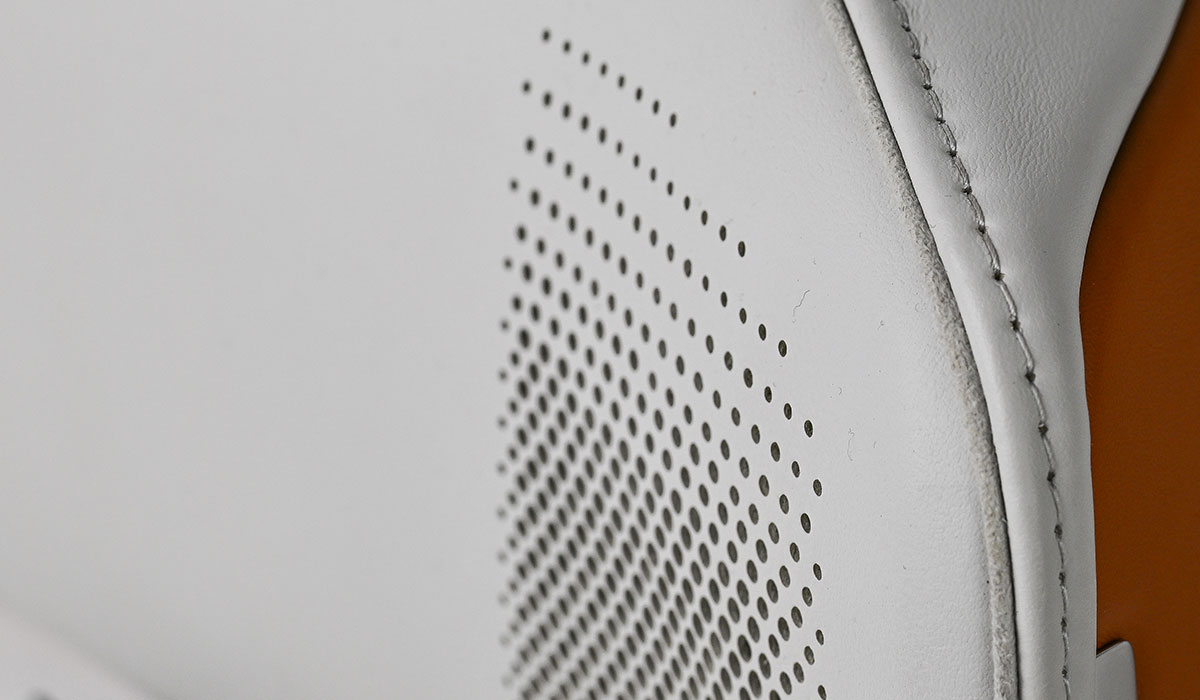

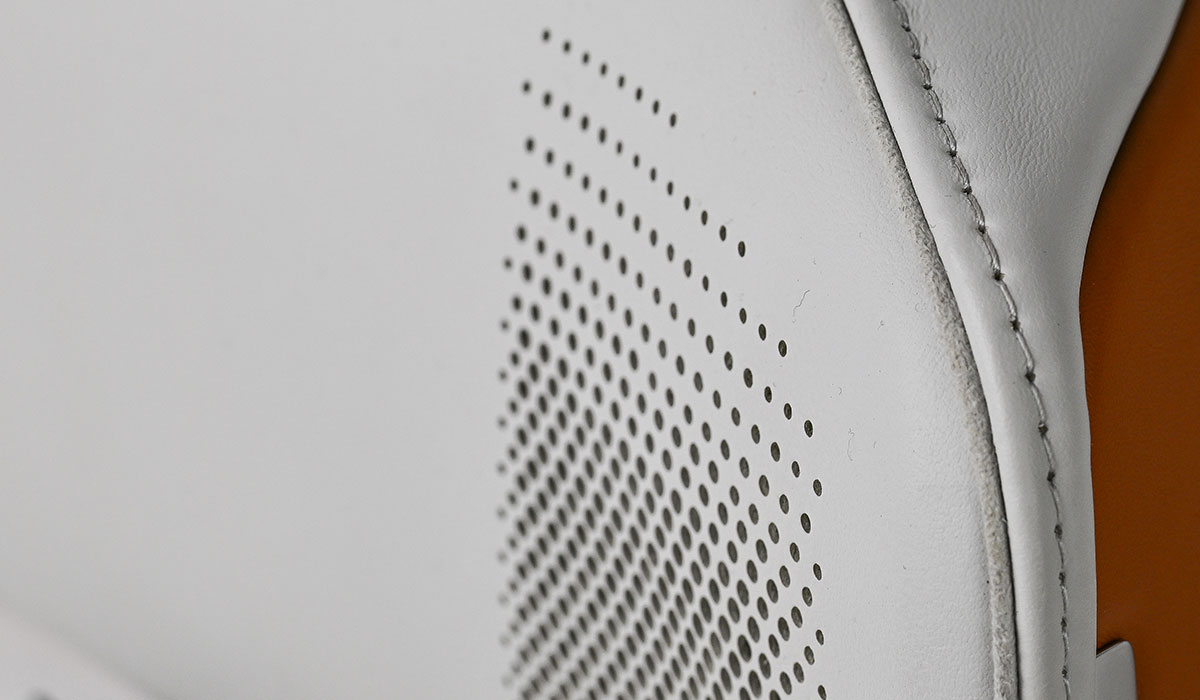

WMG offers specialized trim cut and sew capabilities for the automotive seating industry. We provide precision cutting, sewing, and finishing services for a wide range of automotive fabrics, including leather, synthetic materials, and textiles.

Trim Cut and Sew

WMG offers specialized trim cut and sew capabilities for the automotive seating industry. We provide precision cutting, sewing, and finishing services for a wide range of automotive fabrics, including leather, synthetic materials, and textiles.

Polyurethane Foam Molding

Every year, WMG produces more than 20 million foamed parts including head restraints, arm restraints and more. Each facility within our company has its own foam lines, reducing logistics impacts and inventory levels.

Plastic Injection Molding

WMG specializes in plastic injection molding for automotive interiors, providing end-to-end solutions from design to finished products. With advanced technology and a skilled team, we ensure high-quality components that meet the rigorous standards of the automotive industry.

Plastic Injection Molding

WMG specializes in plastic injection molding for automotive interiors, providing end-to-end solutions from design to finished products. With advanced technology and a skilled team, we ensure high-quality components that meet the rigorous standards of the automotive industry.

Metal Forming & Welding

Windsor Machine has been a leading supplier in metal forming for more than 50 years.

Tooling and Automation

Our company is not only dedicated to designing and building high-quality products, but we also take pride in designing and creating the specialized tools that enable the production of those products. Through our in-house tooling design department, we develop customized tools and equipment tailored specifically to our manufacturing processes.

Tooling and Automation

Our company is not only dedicated to designing and building high-quality products, but we also take pride in designing and creating the specialized tools that enable the production of those products. Through our in-house tooling design department, we develop customized tools and equipment tailored specifically to our manufacturing processes.

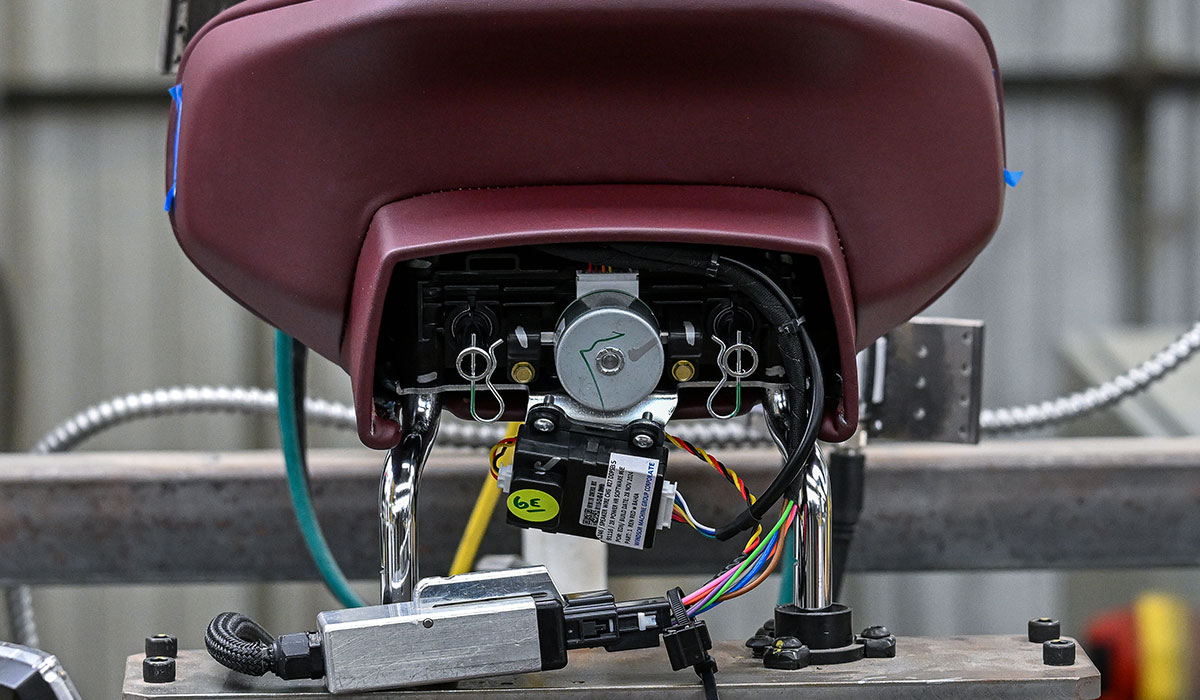

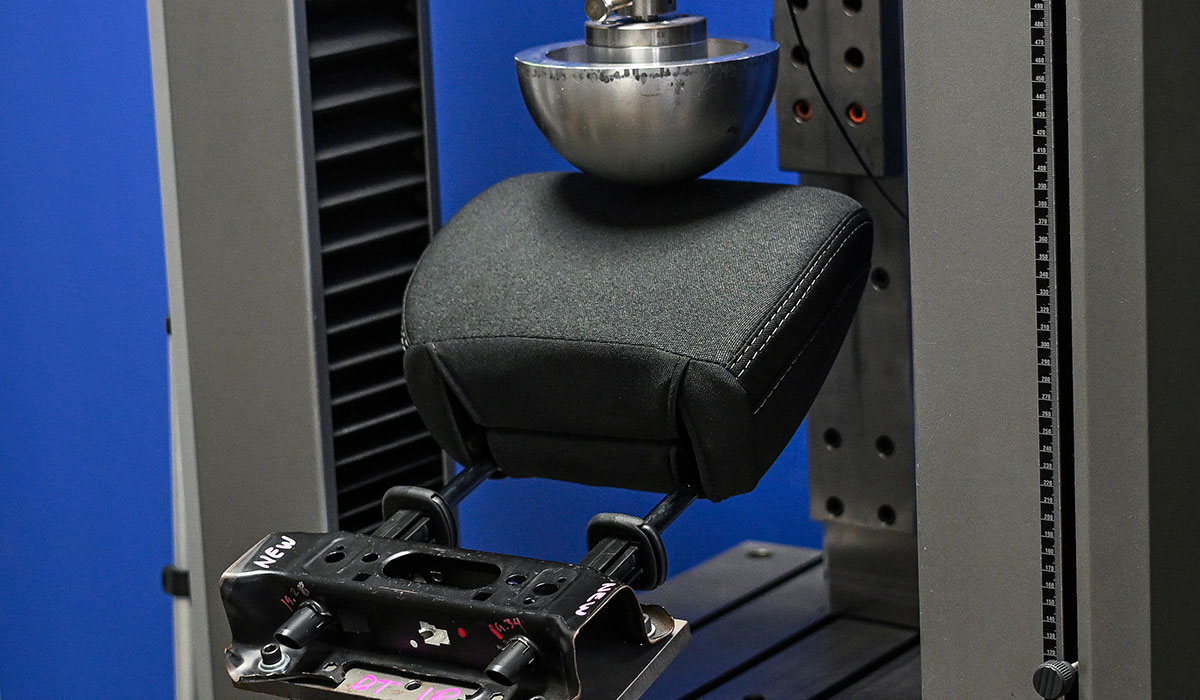

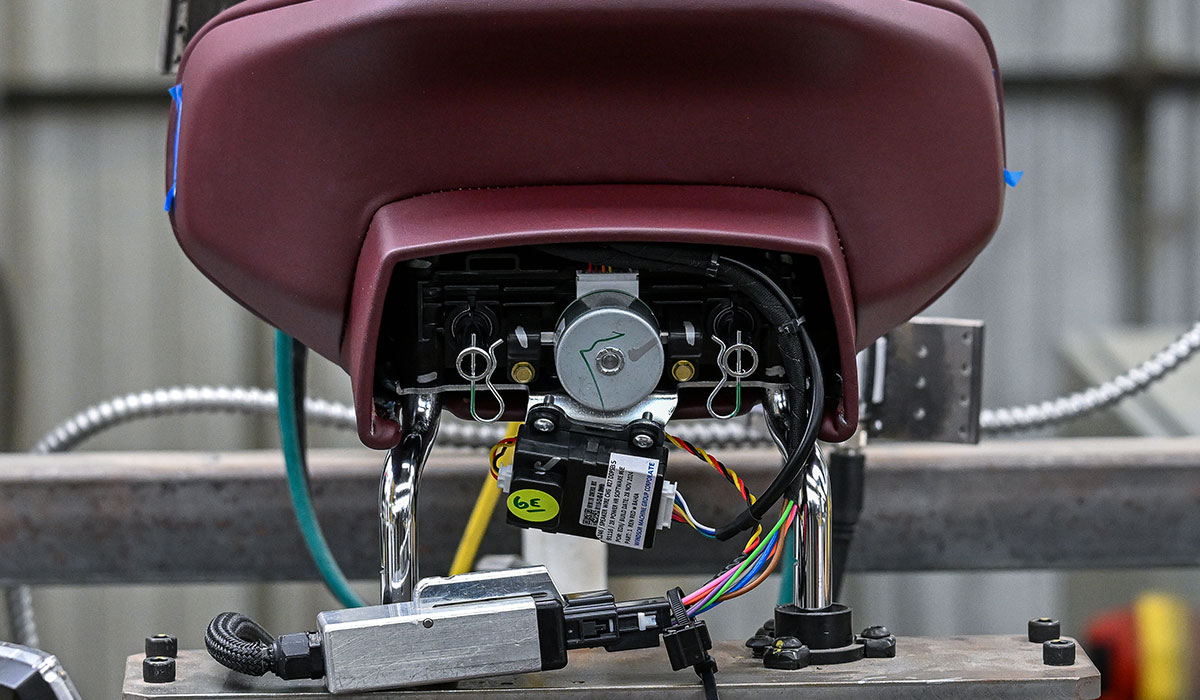

Prototyping and Testing

WMG runs its own standalone prototype facility to ensure that our engineers and our customers have reliable prototypes for initial design validation.

Quality and Reliability

Our company employs advanced detection systems throughout our assembly lines to ensure that every product shipped to customers is of the highest quality and free from defects.

Quality and Reliability

Our company employs advanced detection systems throughout our assembly lines to ensure that every product shipped to customers is of the highest quality and free from defects.