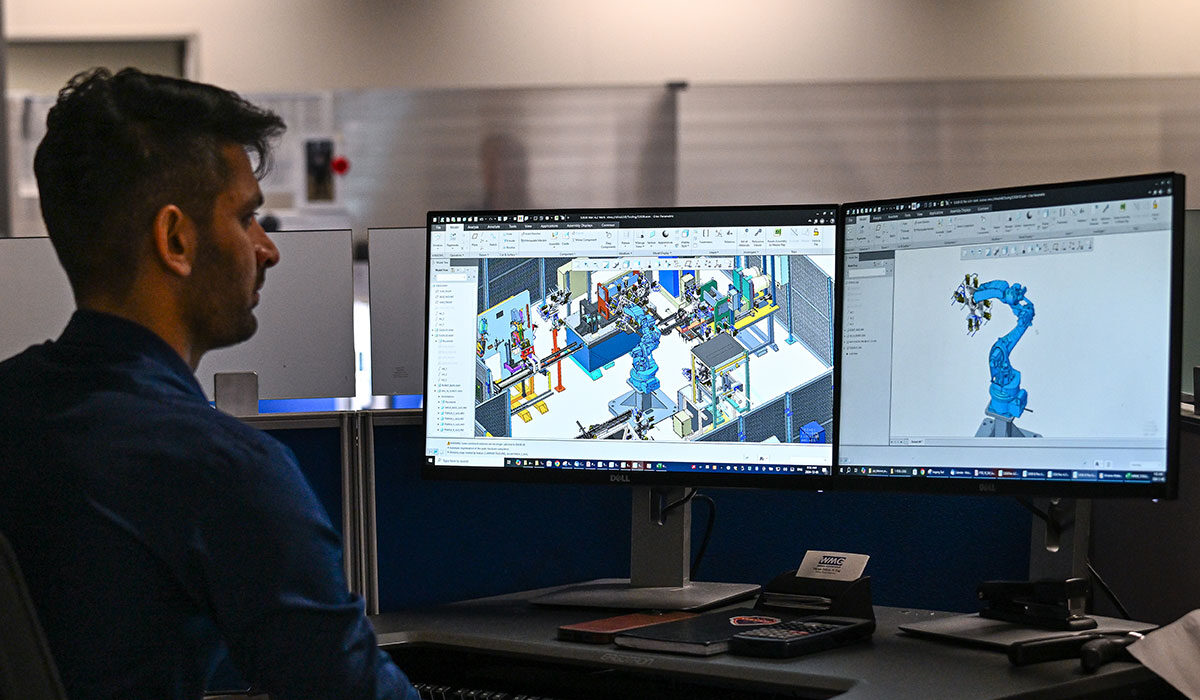

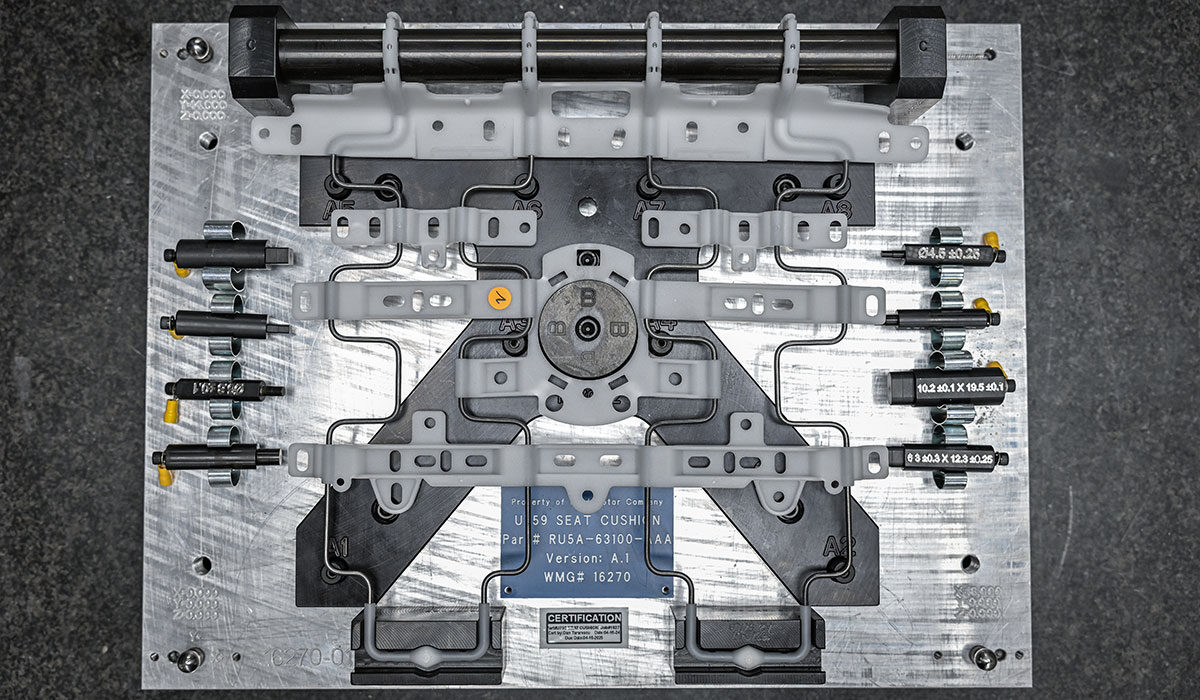

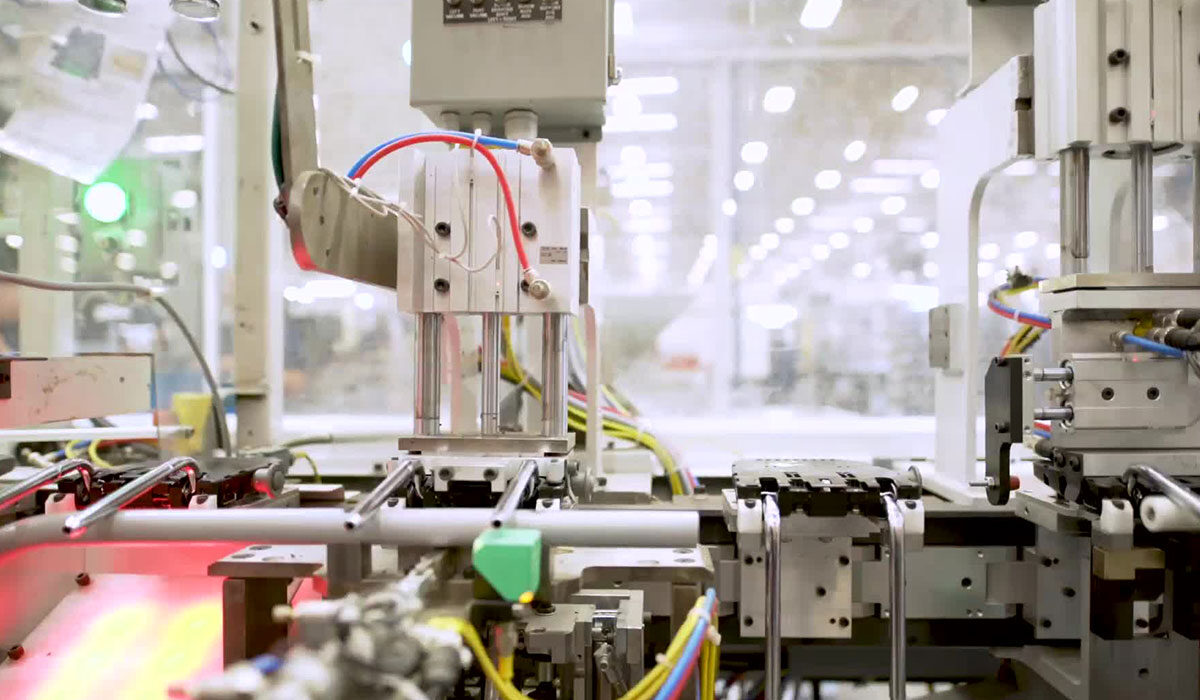

Our company is not only dedicated to designing and building high-quality products, but we also take pride in designing and creating the specialized tools that enable the production of those products. Through our in-house tooling design department, we develop customized tools and equipment tailored specifically to our manufacturing processes. This unique capability allows us to have full control over the production cycle, ensuring that our products meet the highest standards of quality and precision.

By designing our own tools, we can optimize production efficiency, reduce costs, and shorten lead times. This integrated approach enables us to address complex design challenges and implement innovative solutions quickly. Our commitment to both product and tool design gives us a competitive edge, allowing us to deliver superior products while maintaining flexibility and control throughout the entire manufacturing process.

Capabilities: