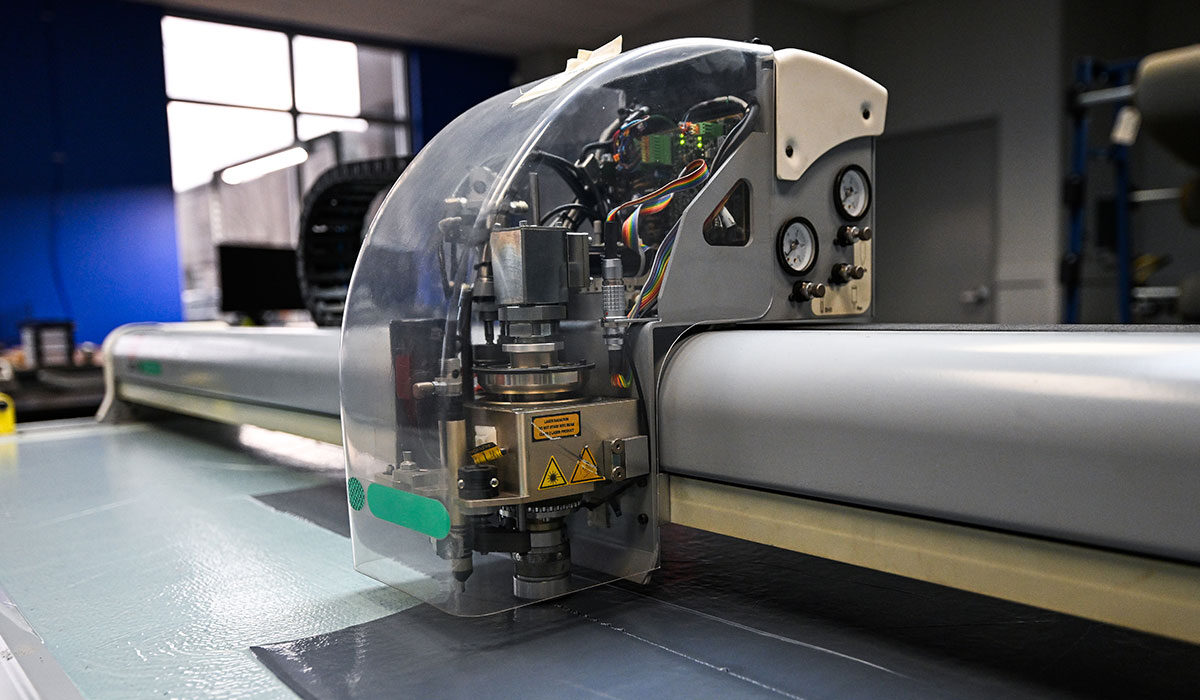

WMG offers specialized trim cut and sew capabilities for the automotive seating industry. We provide precision cutting, sewing, and finishing services for a wide range of automotive fabrics, including leather, synthetic materials, and textiles. With a focus on quality and durability, WMG ensures that each component meets the strict standards required for automotive interiors. Our advanced manufacturing techniques, machinery and skilled workforce allow for the production of high-quality trim products delivering both comfort and style for vehicles while maintaining efficiency and consistency in high-volume production.

Precision in Every Cut, Perfection in Every Stitch

More than 50,000 Trim Covers Sewn Per Day

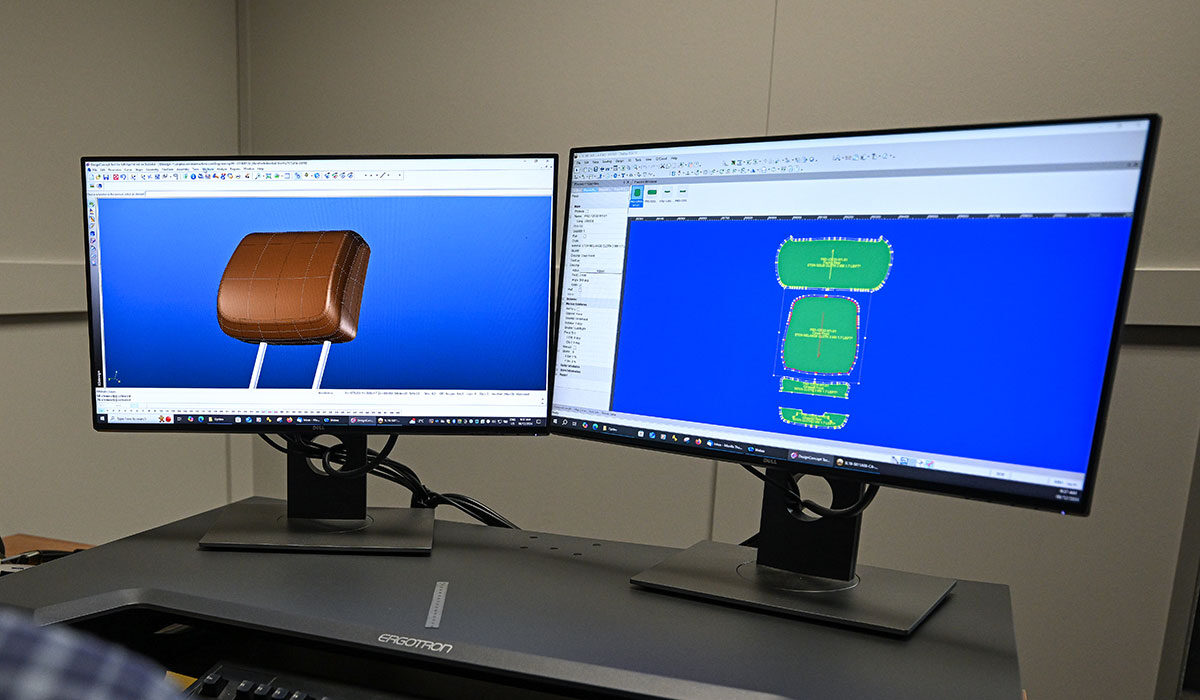

Leather Wrapping

Our company specializes in high-quality leather wrapping for automotive seating, combining precision craftsmanship with premium materials. We offer a range of leather options, ensuring a durable, comfortable, and luxurious finish. Our skilled team delivers flawless, custom-fit seating solutions that enhance the interior of any vehicle, elevating both style and comfort.