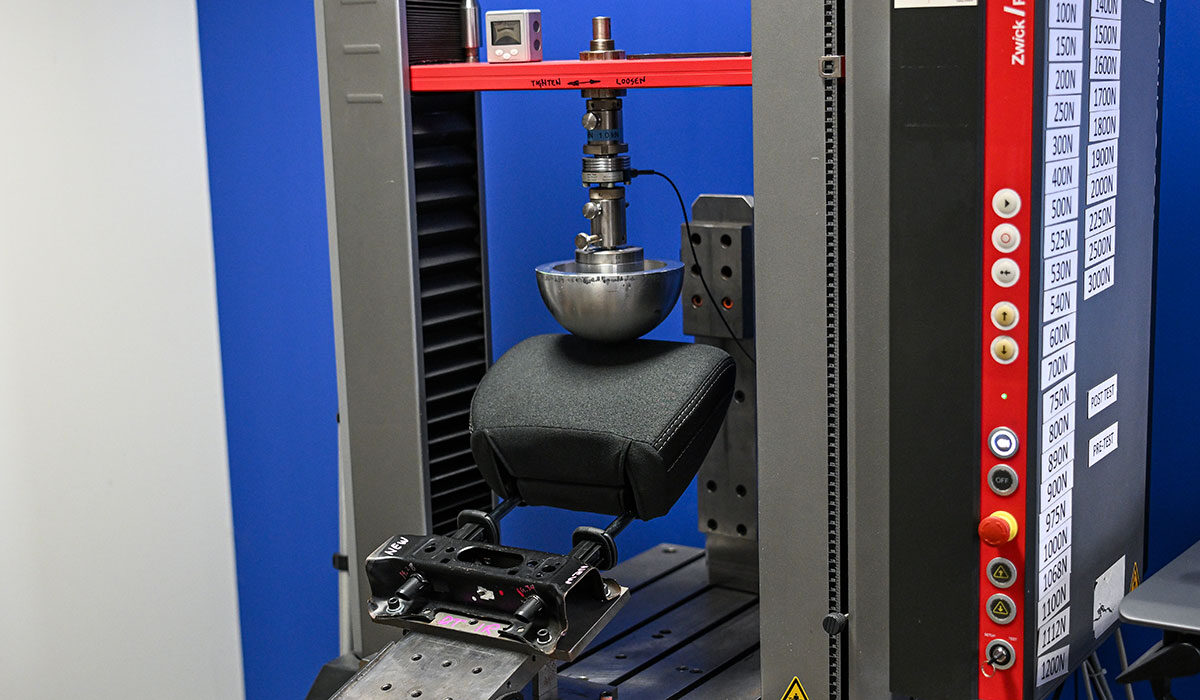

WMG runs its own standalone prototype facility to ensure that our engineers and our customers have reliable prototypes for initial design validation.

From 3D printing, foam prototyping, CNC machining, injection molding, tube forming to welding we do it all in house. Our customers can get affordable, high quality prototype products within days and many times within hours. Accompanied with an in house CMM and 3D scanning, each product we prototype in house is quality-checked before it leaves our doors. Having access to such a facility, our engineers can rapidly accelerate our design validation to save you time and money.